01 Feb Staying ahead of the curve with modular conveyor chain

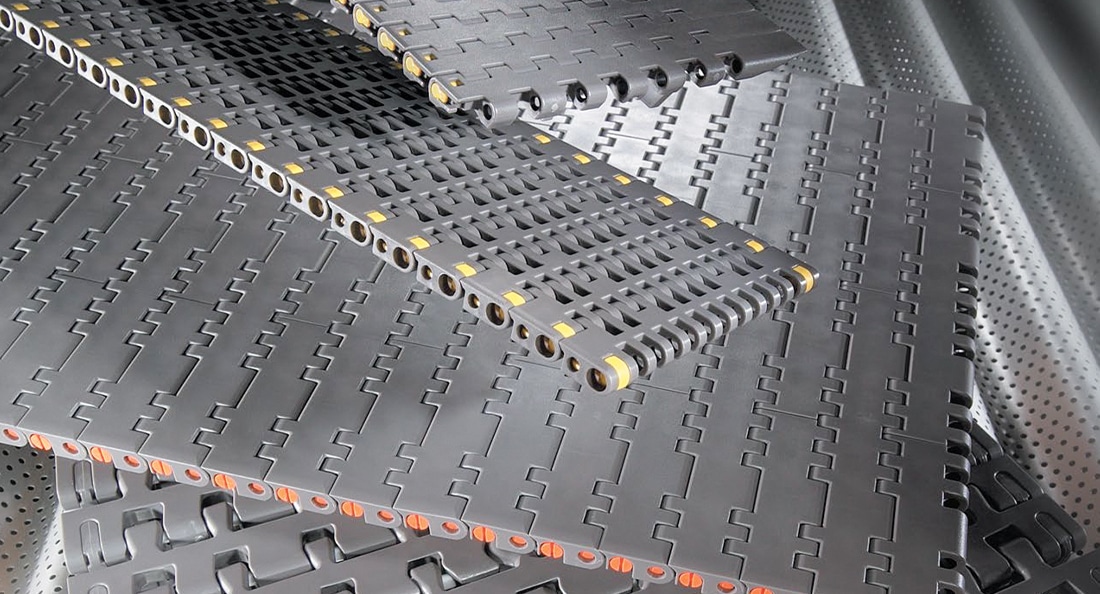

If a conveyor breaks down at a food production plant, it can halt production and incur loss of valuable perishable product, explains Troy Markland, Motion Australia’s Product Manager for Power Transmission. “For this reason, it is absolutely critical for plant workers to keep up with regular...