20 Jun Safeguarding health and safety with Fanmaster

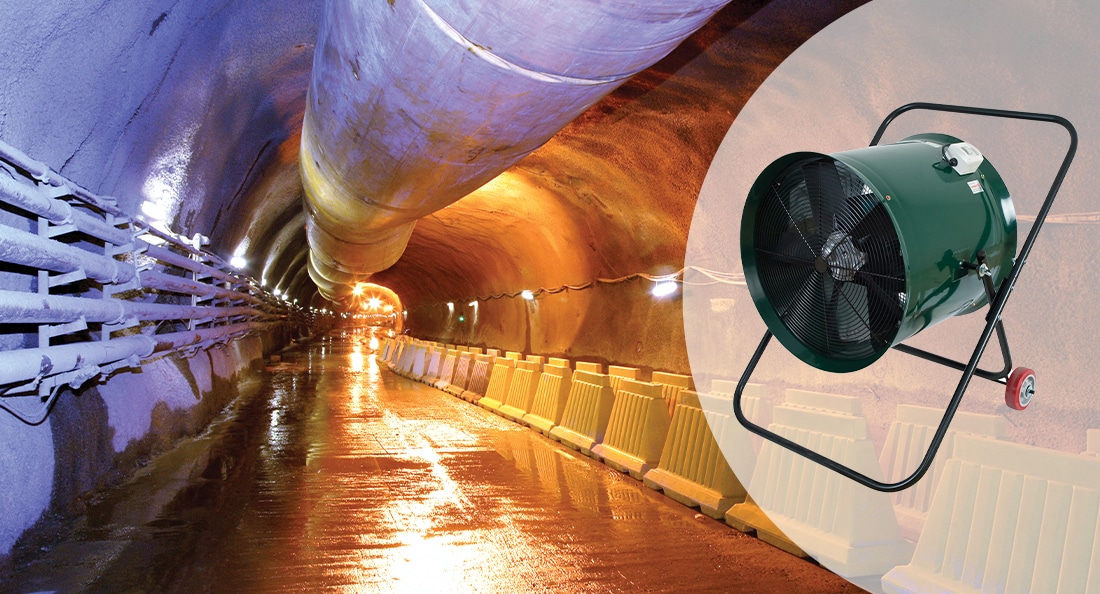

Maintaining high standards of occupational health and safety practice is paramount in underground mines, where ventilation plays a vital role. Workers in these environments are regularly exposed to pollutants such as gases, dust, and fumes, which can have significant short and long-term health consequences with...