21 May Schaeffler seals the deal with top of line sealed bearings

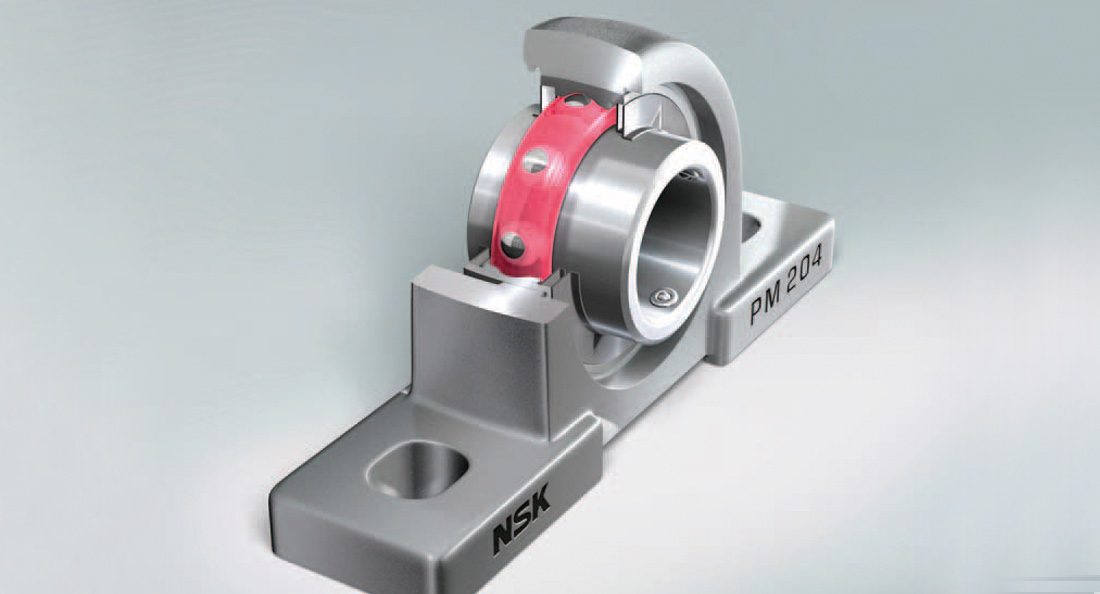

When it comes to protecting bearings from contamination and water washdowns on mine sites, sealed spherical roller bearings provides an additional barrier for protecting bearings, as Tony Tormey, BSC’s Product Manager for Industrial Bearings explains. The Schaeffler Group has been pioneering the roller bearing industry, with the Schaeffler...