12 Jul Schaeffler’s same-day solution

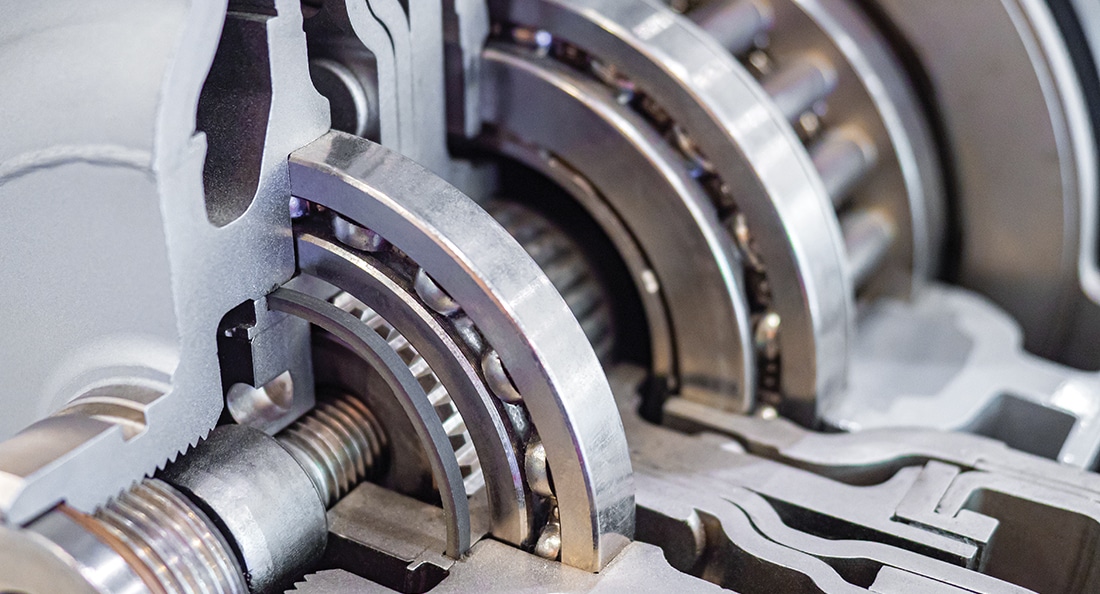

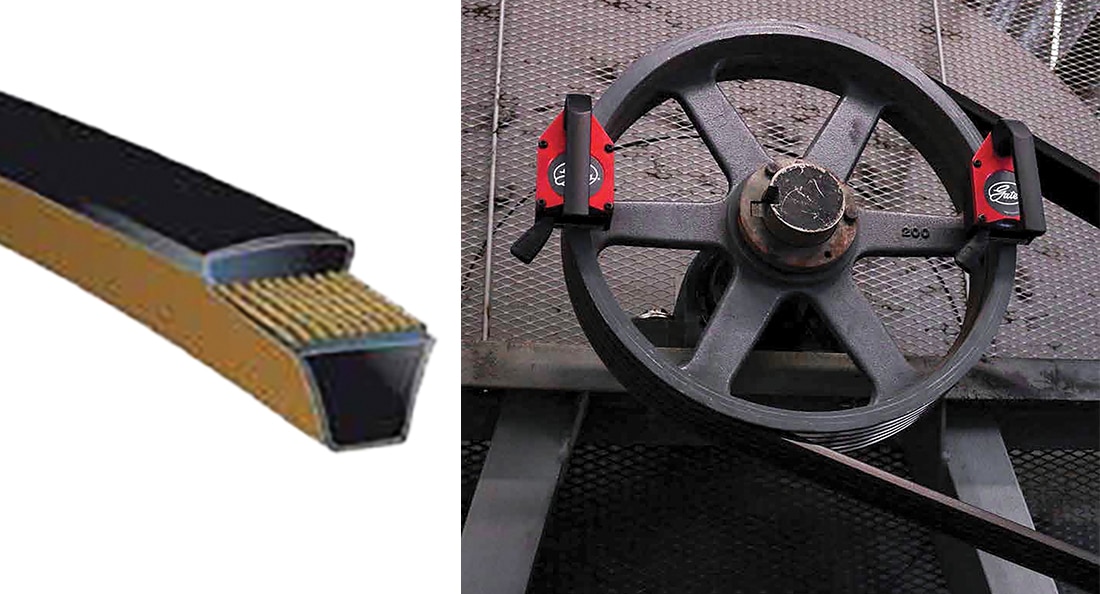

In a critical situation where a pulp and paper factory faced a breakdown of its refiner bearings and lacked suitable replacements, they turned to Schaeffler, a renowned global supplier of automotive and industrial components. Offering valuable insights, Matt Thornton, Branch Manager at Motion, sheds light...