NSK Tag

23 Jun Lubed-for-life bearings drive improved efficiency

Bearing failures are always an unwanted hassle for industrial plants, particularly so if they lead to shutting down a critical operation. Tony Tormey, BSC’s Product Manager for Industrial Bearings, says water and dust ingress is a major cause for bearing failures in industrial settings. As a...

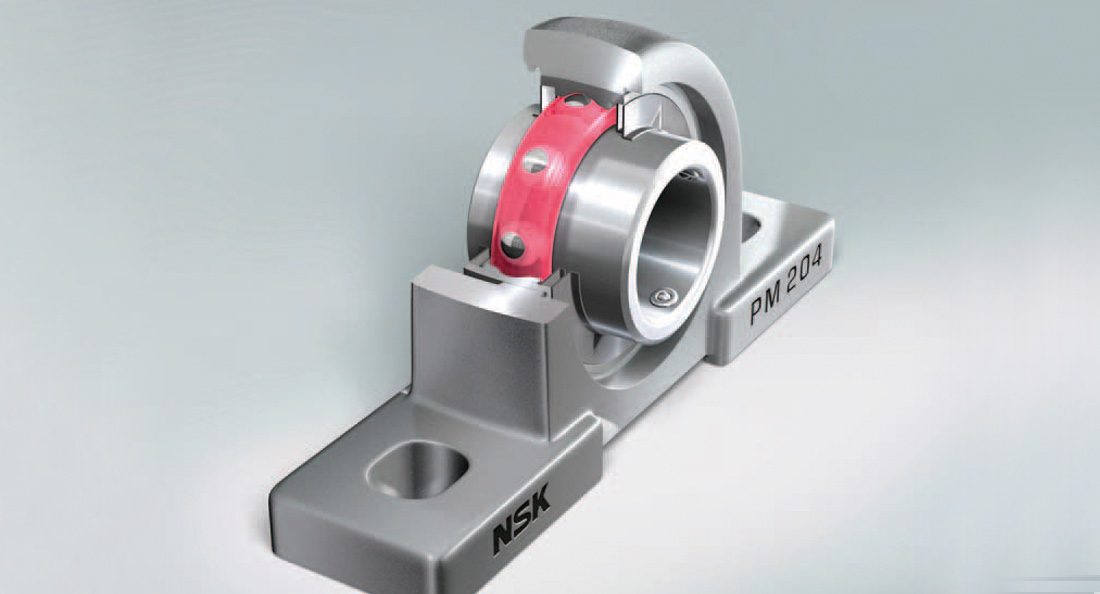

01 Jun A set-and-forget solution with Molded-OilTM bearings

Bearings in the recycling industry are subject to varying levels of temperature and moisture. While conventional bearings use grease or oil to keep the rotating elements running smoothly, solid lubricant bearings, such as the NSK Molded-OilTMbearings, use solid lubricants that do not require any re-lubrication. NSK’s...