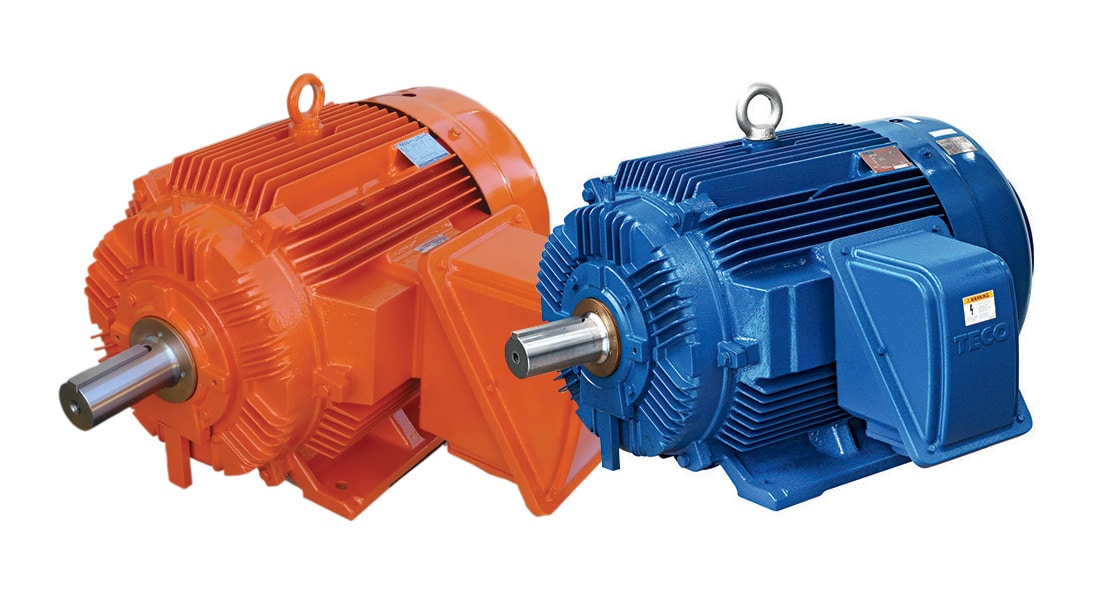

16 May Reducing annual energy costs with high-efficiency motor solutions

On a mining site, equipment such as pumps, heating and ventilation systems, air compressors, and conveyors are all powered by electric motors. The purchase price of these motors represents only a small percentage of their overall operating cost, as each unit can use up to $21,000 worth of energy every year.

“Replacing existing standard motors will immediately reduce a mine site’s annual electricity cost and delivering return on investment in less than 1.5 years,” explains Steve Hittmann, Motion Australia’s National Category Manager for Mechanical Drive Systems and Electric Motors. “In fact, the older the motor and the larger the motor’s kW per hour– the quicker the returns.”

To read the full article, please click here.