19 Dec Autogard torque limiters come through in the clutch

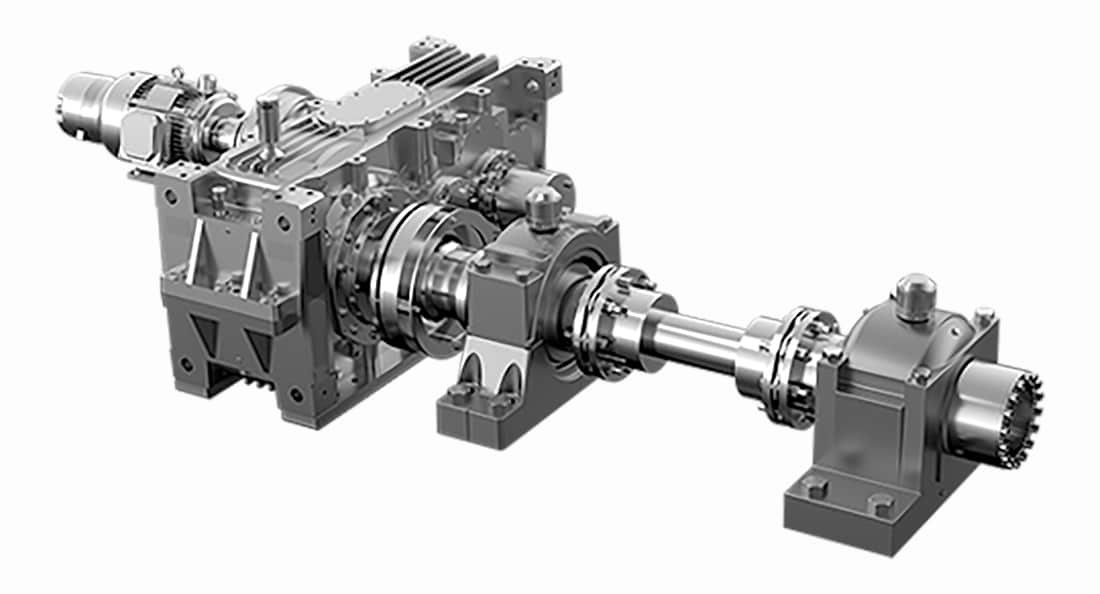

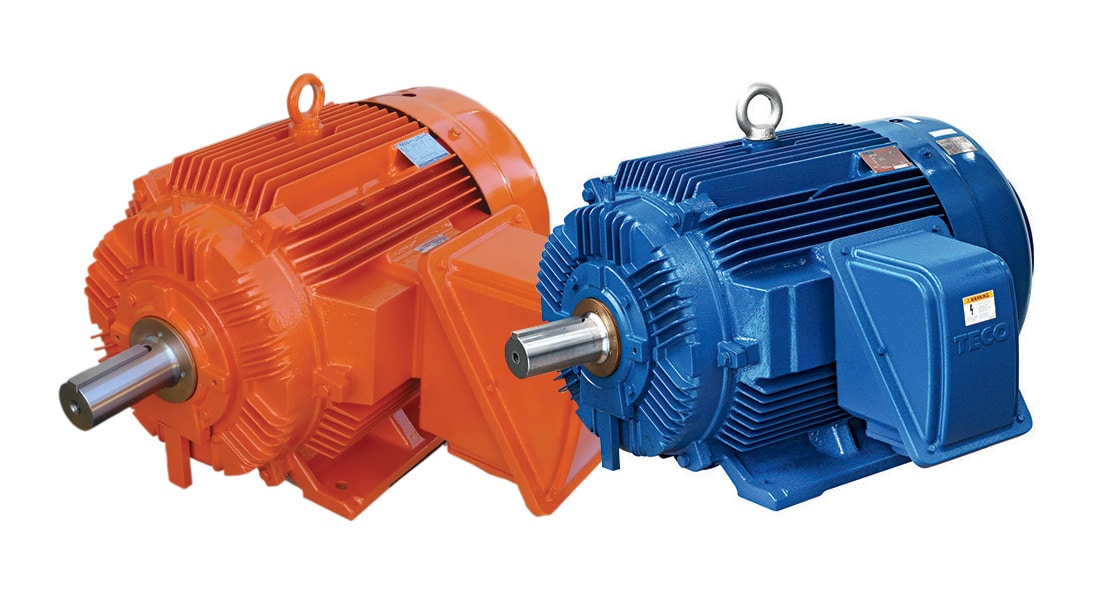

When it comes to predicting a potential failure or breakdown on a piece of equipment, Motion Australia’s Steve Hittmann says that torque limiters play an important role in addressing these challenges. “Torque is the measure of force that causes rotational motion and importantly, it takes into...