22 Jun Keeping desalination equipment tip-top for Northern Water

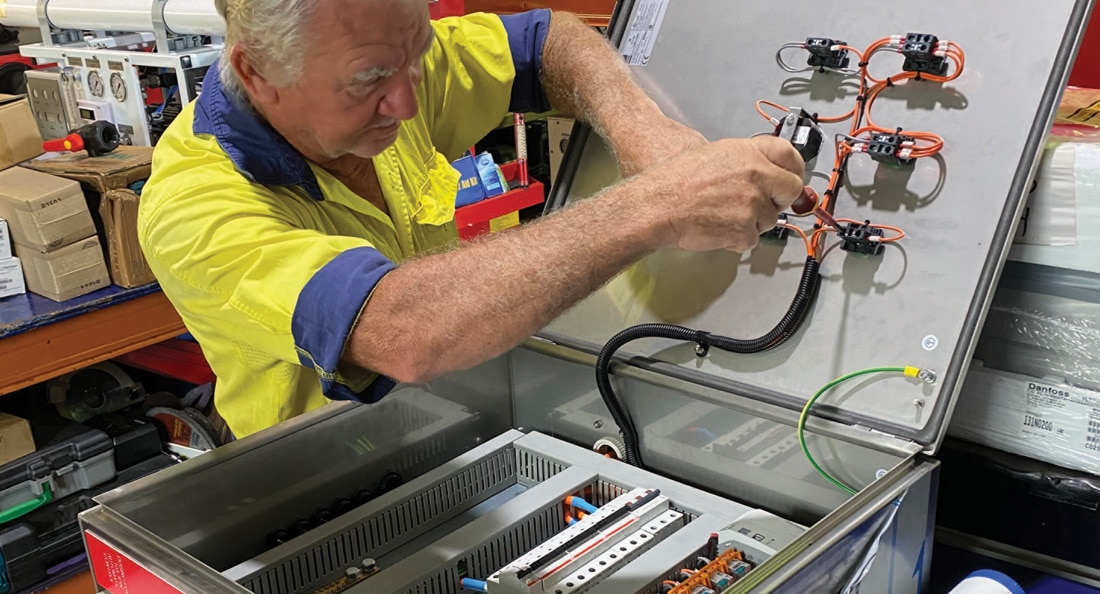

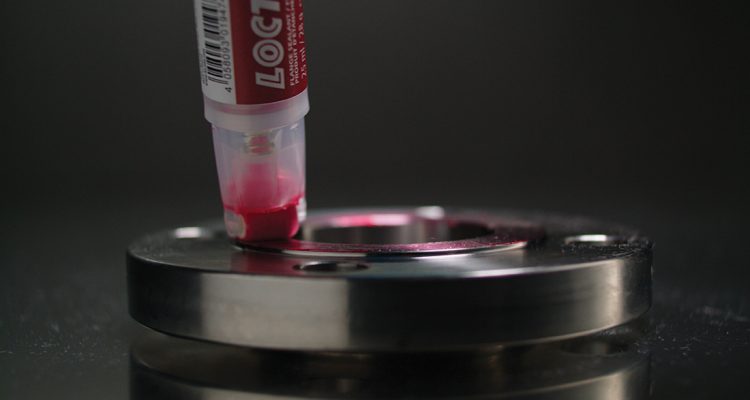

Based in Cairns, Northern Water has been supplying, manufacturing and servicing water treatment equipment for over 17 years. Over this time, the business has built a rapport for having extensive product knowledge and topping this up with quality after-sales support. With a combined experience of over...